When you think of the word turntable, you might think of something that you play a record on, but for this project, at least, we're going to build a different type of turntable. A turntable, in the video and photography world, is a flat platform on a stand that spins around, allowing you to get a 360 degree view of an object. This is great for adding movement to video, focusing on details that you otherwise might miss, and to raise an object up for better lighting. Turntables, much like other pieces of production equipment, can carry a premium price tag with minimum features.

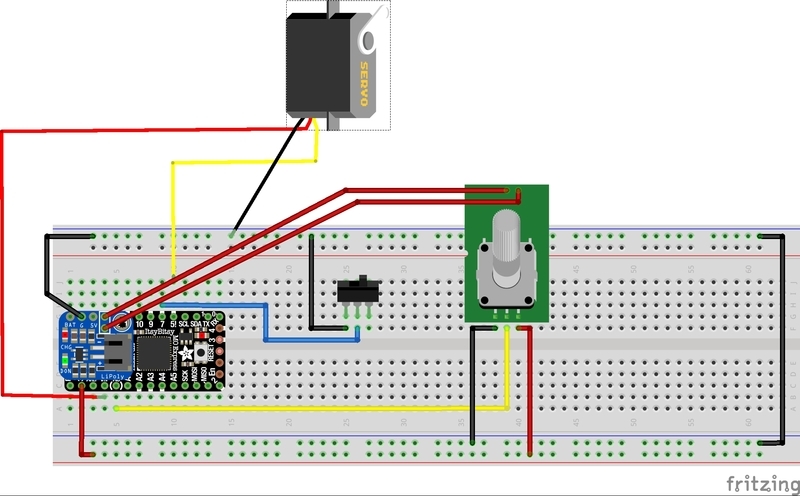

For this project, we'll go over how to build your own turntable with the ability to have adjustable rotation speed, rotate both clockwise and counterclockwise, and 3D print interchangeable platforms.

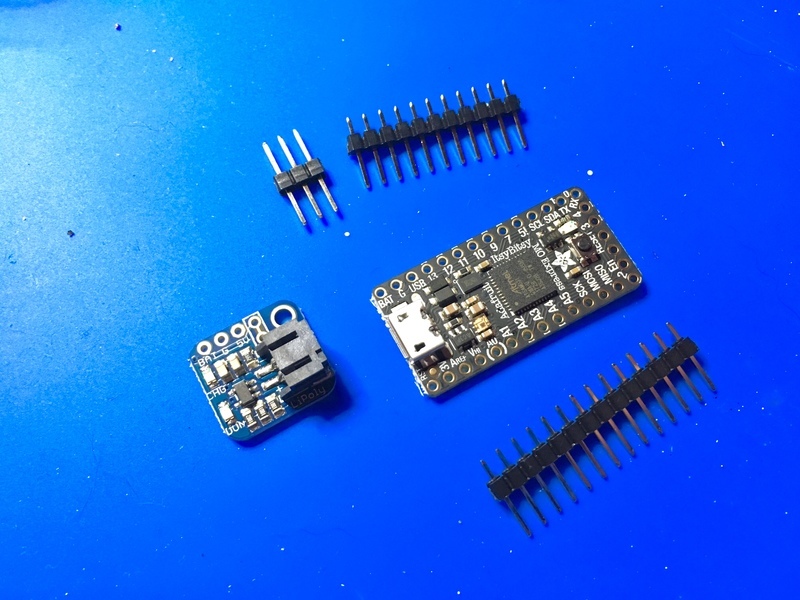

For supplies you'll need: