Stepper Motor

A stepper motor often looks like a continuous DC motor, coming in round or square shapes. You can tell they are different as a stepper motor has four to eight wires coming out if it. The wires inside form coils which allow the shaft of the motor to turn very precisely.

The wire connections must be made to an electrical circuit specially made for controlling a stepper motor as it will not work by putting DC power on the wires.

As shown below, pulses of electricity are sent to the coils in a timed manner to achieve motion.

Steppers can turn in a full circle like DC motors and continuous servos but they can be more expensive and require electronic controllers to achieve their precise movements. Often the shaft is connected to a belt or gear for moving something.

Examples of steppers being used are with scanners, plotters, 3-D printers, etc.

Use of a Stepper with a Belt System

A belted system provides excellent control over moving something. Most plotters, CNC machines, and 3-D Printers use some variation of belts for accuracy.

Adafruit carries the GT2 belt system. There are other systems but GT2 offers advantages noted by Ladyada in this video.

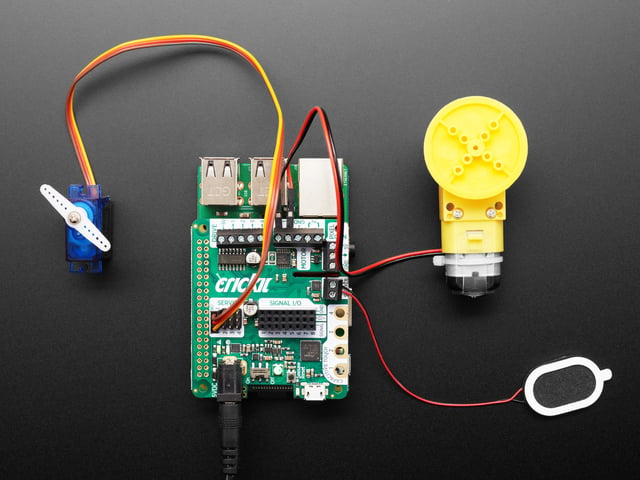

Steppers Available at Adafruit

Adafruit carries a number of steppers in various sizes. There are also couplers which help attach the stepper shaft to your project.