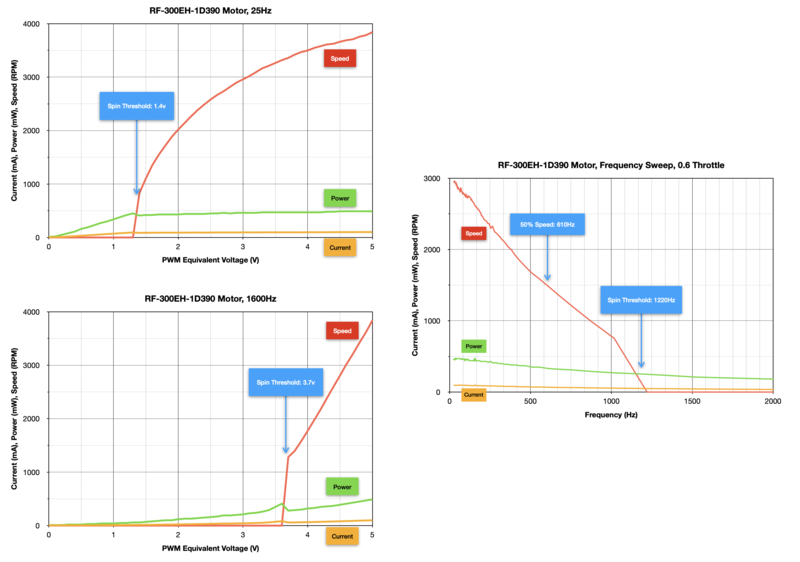

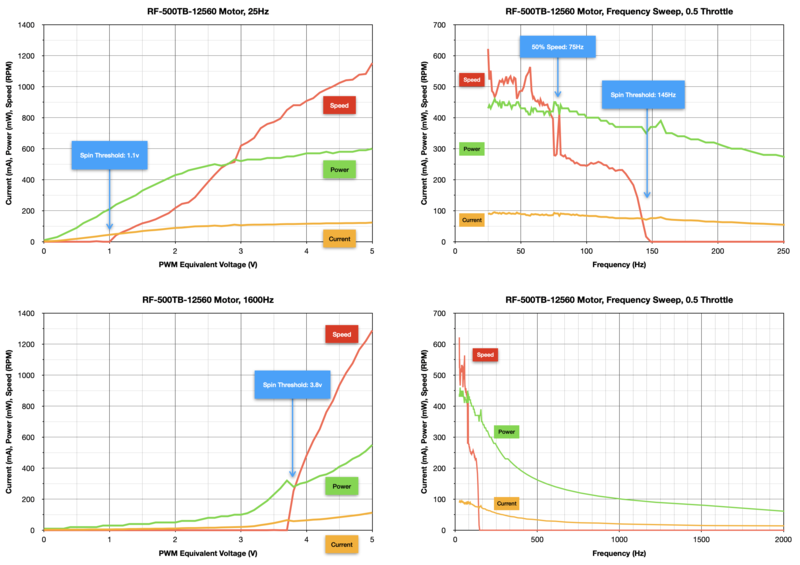

A lower PWM frequency can dramatically improve the slow-speed operation of brushed DC motors. Set your motor controller's PWM frequency below 100Hz and test to see if performance improves.

Jump to the Code Examples section to see how it's done.

Works with:

- CRICKIT FeatherWing

- CRICKIT for Circuit Playground Express

- DC Motor + Stepper FeatherWing

- Motor/Stepper/Servo Shield

- DRV8871 DC Motor Driver Breakout

- DRV8833 DC/Stepper Motor Driver Breakout

- TB6612 1.2A DC/Stepper Motor Driver Breakout

- L9110H H-Bridge Motor Driver

- L293D Dual H-Bridge Motor Driver

Supporting code libraries: