Epoxy resin river tables can be stunning works of art. Adding NeoPixels and a Circuit Playground give this table an extra special dimension -- its soft pulsing glow fills a room with beauty and makes every meal into a masterpiece.

I love waking up with the sunrise and sipping tea with the softly glowing river beneath my mug, and coming home at night to eat a delicious meal set off by the gorgeous wood grain and slowly shifting rainbow colors. It's the centerpiece of my living space and it brings me joy every single day.

This was my first attempt at building furniture and I'm very pleased with how it turned out. This was not an easy build! The electronics are fairly simple and straightforward, but the woodworking and larger-scale resin pouring was new territory for me, and I made a lot of mistakes (but I sure learned a lot!) I would love to see an experienced woodworker take this idea and run with it!

Table Materials

- A slab of live-edge wood -- I used walnut. Look for local suppliers and spend a fun afternoon perusing the selection.

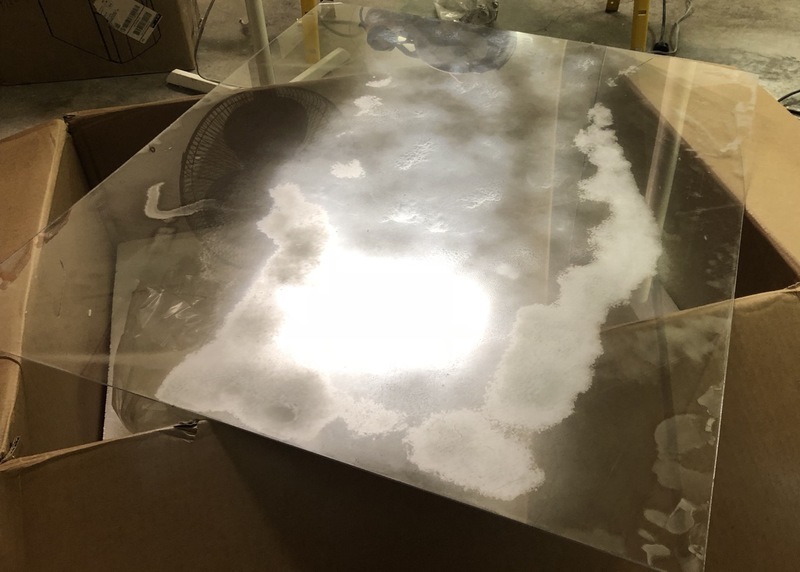

- Deep Pour Epoxy Resin -- you'll need a lot.

- Polyethylene plastic for building your pour mold -- I got this at my local Tap Plastics, cut to size

- Hot Glue for building the pour mold

- Dye or color for the resin (optional) - I found some blue resin dye at my local craft store in a dropper bottle

- Propane torch (or creme brulee torch) for getting rid of bubbles

- Mixing buckets, gloves, stirring sticks, lots and lots of drop cloths and cleanup gear

- Woodworking tools for prepping and sanding the wood

Other Build Materials

- Acrylic sheet for holding the NeoPixels

- Silicone Glue

- Mirror Effect Spray paint

- Table legs & hardware