A Feather board without ambition is a Feather board without FeatherWings! This is the DC Motor + Stepper FeatherWing which will let you use 2 x bi-polar stepper motors or 4 x brushed DC motorx (or 1 stepper and 2 DC motors). Using our Feather Stacking Headers or Feather Female Headers you can connect a FeatherWing on top or bottom of your Feather board and let the board take flight!

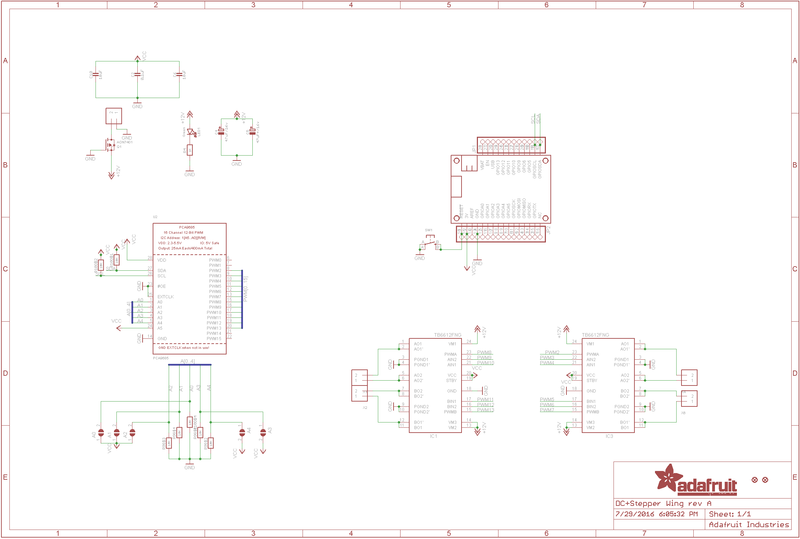

The original Adafruit Motorshield Kit is one of our most beloved shields, which is why we decided to squish it all together on a FeatherWing to make something even smaller, lighter, and more portable! Instead of using a latch and the Arduino's PWM pins, we have a fully-dedicated PWM driver chip onboard. This chip handles all the motor and speed controls over I2C.

Since the FeatherWing only uses the I2C (SDA & SCL pins), it works with any and all Feathers. You can stack it with any other FeatherWing or with itself (just make sure you have each wing with a unique I2C address) Check out our range of Feather boards here.

Motor FeatherWing Specs:

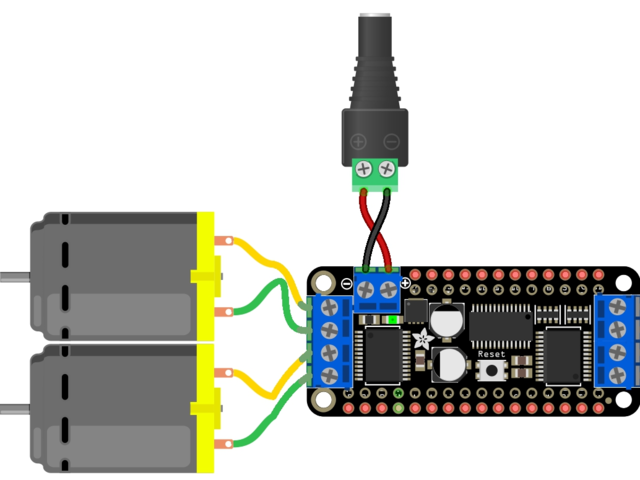

- 4 full H-Bridges: the TB6612 chipset provides 1.2A per bridge with thermal shutdown protection, internal kickback protection diodes. Can run motors on 4.5VDC to 13.5VDC.

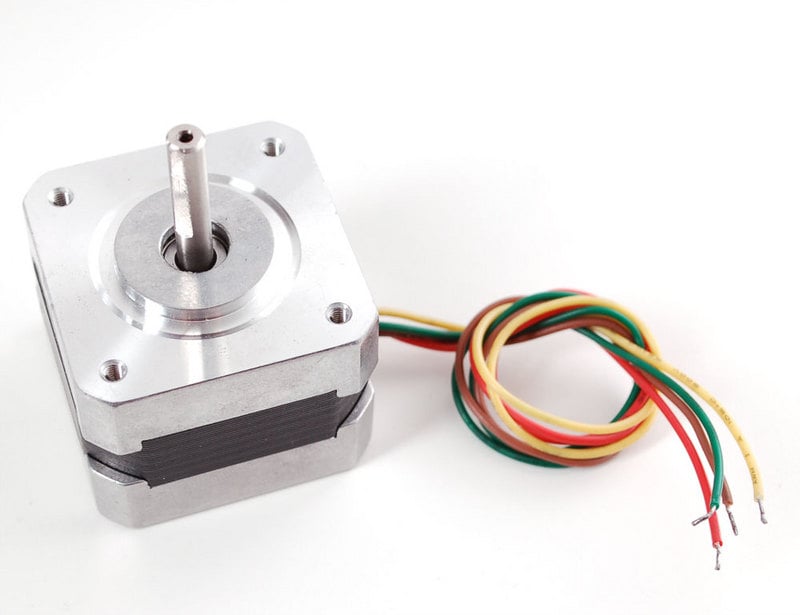

- Up to 4 bi-directional DC motors with individual 12-bit speed selection (so, about 0.02% resolution)

- Up to 2 stepper motors (unipolar or bipolar) with single coil, double coil, interleaved or micro-stepping.

- Motors automatically disabled on power-up

- Big 3.5mm terminal block connectors to easily hook up wires (18-26AWG) and power

- Polarity protected 2-pin terminal block and jumper to connect external power, for separate logic/motor supplies

- Completely stackable design: 5 address-select jumper pads means up to 32 stackable wings: that's 64 steppers or 128 DC motors! What on earth could you do with that many steppers? I have no idea but if you come up with something send us a photo because that would be a pretty glorious project.

- Download the easy-to-use Arduino software library, check out the examples and you're ready to go!

Comes with an assembled & tested FeatherWing, terminal blocks & plain header. Some soldering is required to assemble the headers on. Stacking headers not included, but we sell them in the shop so if you want to stack shields, please pick them up at the same time. Feather and motors are not included but we have lots of motors in the shop. You can use any DC or stepper motors that run from 4.5-13.5VDC and draw under 1.2A per coil. You'll likely also need to provide some external power supply for your motors, since its not suggested you run motors from the Feather's lipoly battery.