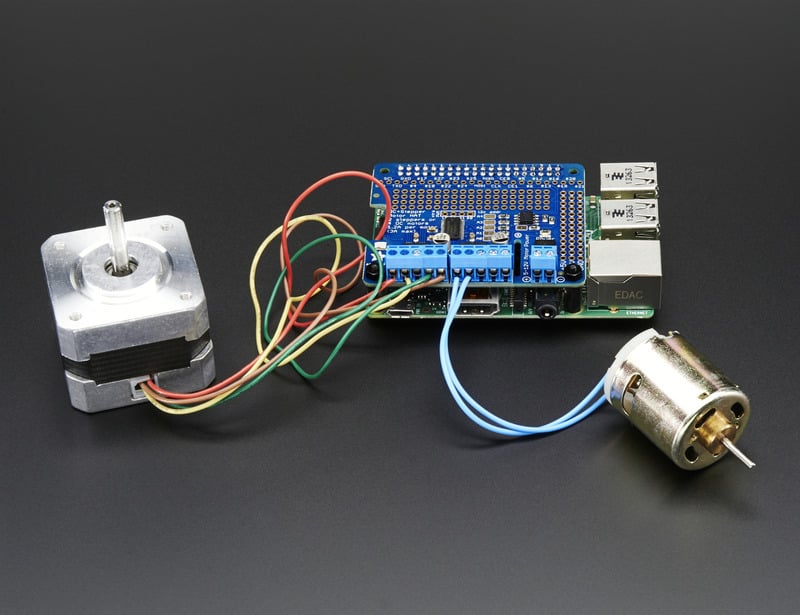

Let your robotic dreams come true with the new DC+Stepper Motor HAT from Adafruit. This Raspberry Pi add-on is perfect for any motion project as it can drive up to 4 DC or 2 Stepper motors with full PWM speed control.

Raspberry Pi and motors are not included

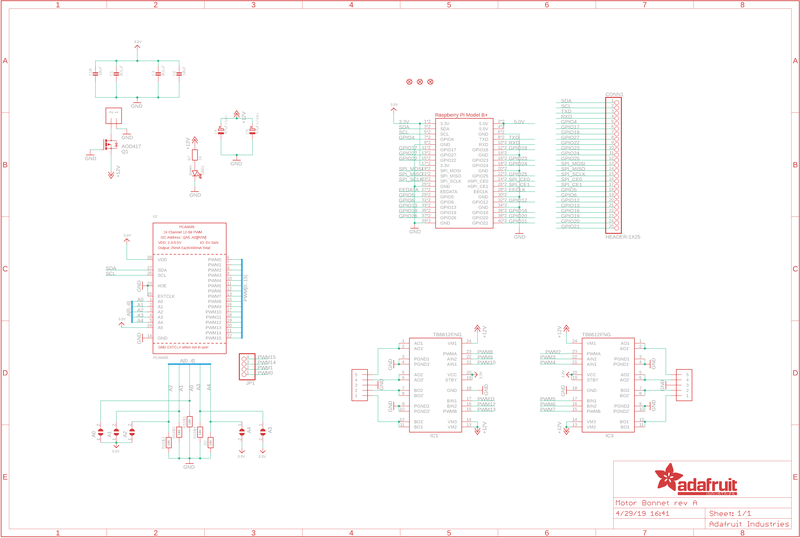

Since the Raspberry Pi does not have a lot of PWM pins, we use a fully-dedicated PWM driver chip onboard to both control motor direction and speed. This chip handles all the motor and speed controls over I2C. Only two GPIO pins (SDA & SCL) are required to drive the multiple motors, and since it's I2C you can also connect any other I2C devices or HATs to the same pins.

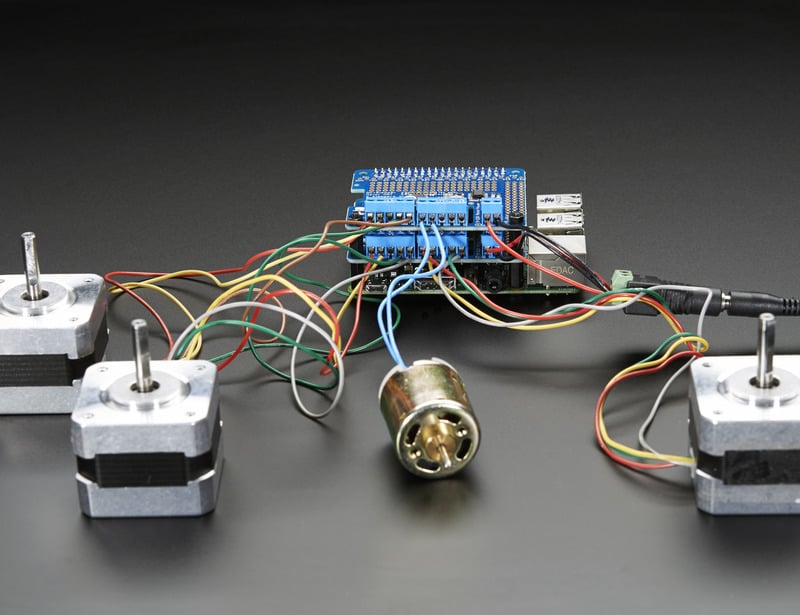

In fact, you can even stack multiple Motor HATs, up to 32 of them, for controlling up to 64 stepper motors or 128 DC motors - just remember to purchase and solder in a stacking header instead of the one we include.

Motors are controlled TB6612 MOSFET driver: with 1.2A per channel current capability (20ms long bursts of 3A peak), a big improvement over L293D drivers and there are built-in flyback diodes as well.

We even had a little space so we added a polarity protection FET on the power pins and a bit of prototyping area. And the HAT is assembled and tested here at Adafruit so all you have to do is solder on the included 2x20 plain header and the terminal blocks.

Lets check out these specs again:

- 4 H-Bridges: TB6612 chipset provides 1.2A per bridge (3A brief peak) with thermal shutdown protection, internal kickback protection diodes. Can run motors on 4.5VDC to 13.5VDC.

- Up to 4 bi-directional DC motors with individual 8-bit speed selection (so, about 0.5% resolution)

- Up to 2 stepper motors (unipolar or bipolar) with single coil, double coil, interleaved or micro-stepping.

- Big terminal block connectors to easily hook up wires (18-26AWG) and power

- Polarity protected 2-pin terminal block and jumper to connect external 5-12VDC power

- Works best with Raspberry Pi model B+ and A+, but can be used with a model A or B if you purchase a 2x13 extra-tall header and solder that instead of the 2x20

- Install the easy-to-use Python library, check out the examples and you're ready to go!

Comes with an assembled & tested HAT, terminal blocks, and 2x20 plain header. Some soldering is required to assemble the headers on. Stacking header not included, but we sell them in the shop so if you want to stack HATs, please pick one up at the same time.

Raspberry Pi and motors are not included but we have lots of motors in the shop and all our DC motors, and stepper motors work great.