Our 19" (500mm) slide rail is made of stainless steel features plenty of mounting holes that can support up to 5 pounds. The sliding ball-bearing platform slides smoothly along the railing.

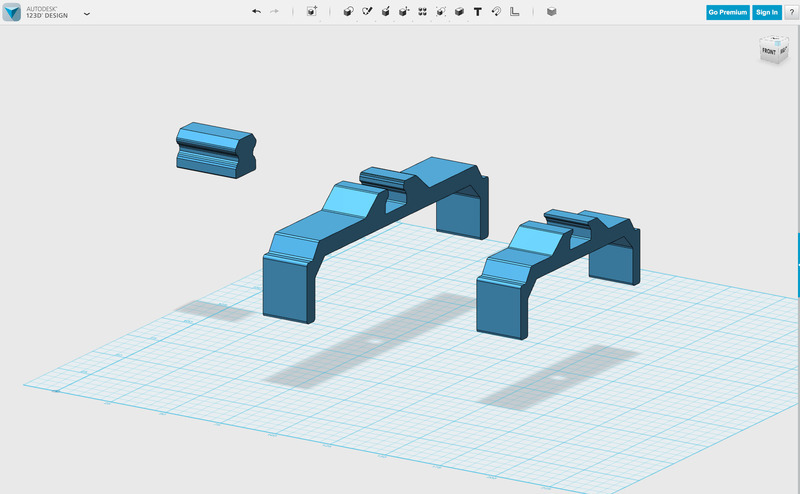

These 3d printed feet slide onto the ends and secured into place with machine screws. This keeps the sliding platform from coming off the railing.

Parts & Supplies

- Supported Slide Rail

- Slide Railing Platform

- 4x #6 32 x 1 in screws with nuts

- 2x #6 32 x 3/4 in screws with nuts

- Fluid Video Head

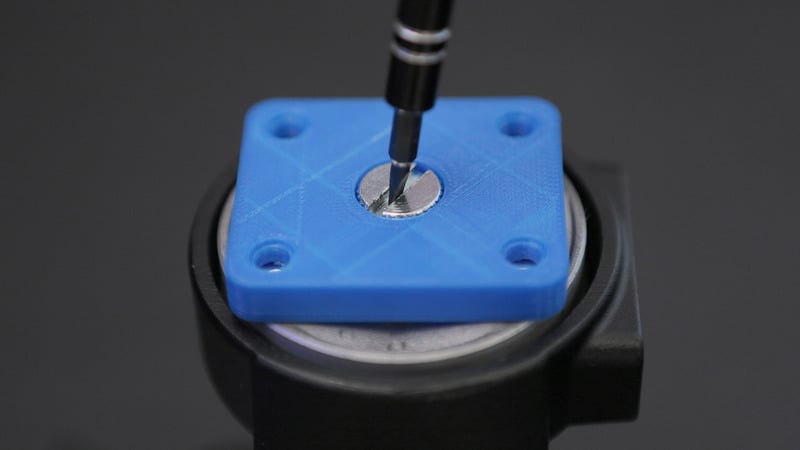

- 3/8" to 1/4" Adapter Screw

- Shoe Mount / Bracket

- Swivel-Head Pan Tilt

- 1/4" Screw with D-Ring